Building technology to enhance lives

We’re not just in the business of manufacturing devices. We’re in the business of enhancing lives. That’s why our team stop at nothing to ensure our clients’ PCBAs & devices are built on time, to world-class standards. That’s why we’re trusted by global leaders in MedTech, GreenTech and key sectors. And it’s why we have one of the largest smart factories in Europe, manufacturing in the UK for international distribution.

WHAT WE DO

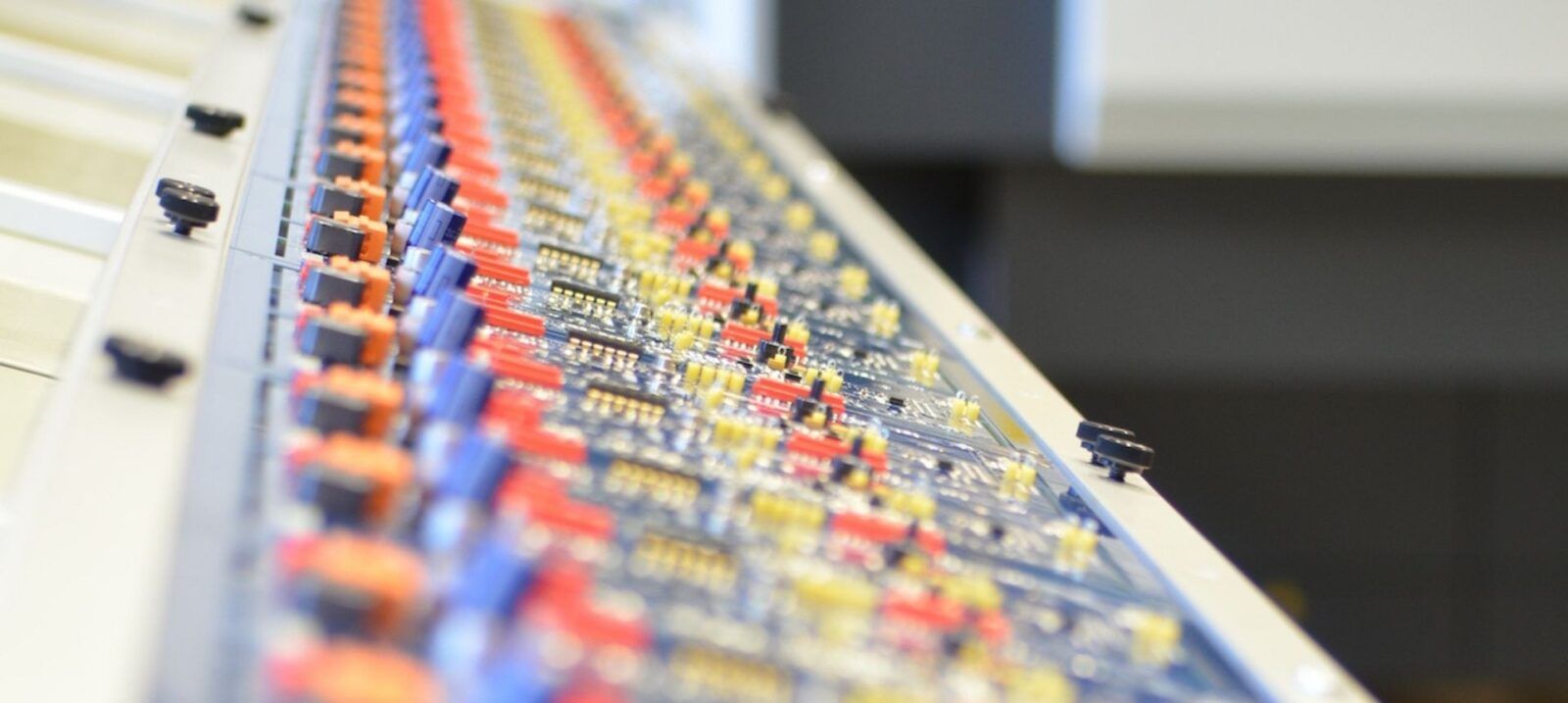

PCBA

Whether you want a fast track PCB prototype, volume PCBA for NPI, or are ready for series production, we have a PCB Assembly route to suit.

Device Build

We have over 30 years experience in supplying full device build, assembled, tested and commissioned to your specification, IPC630 and J-Std standards and to ISO 13485 requirements.

Test

Cogent Technology offers a comprehensive range of PCB and electronic functional testing services, from power checks, programming, XJTAG and AOI through to calibration and product conformance.

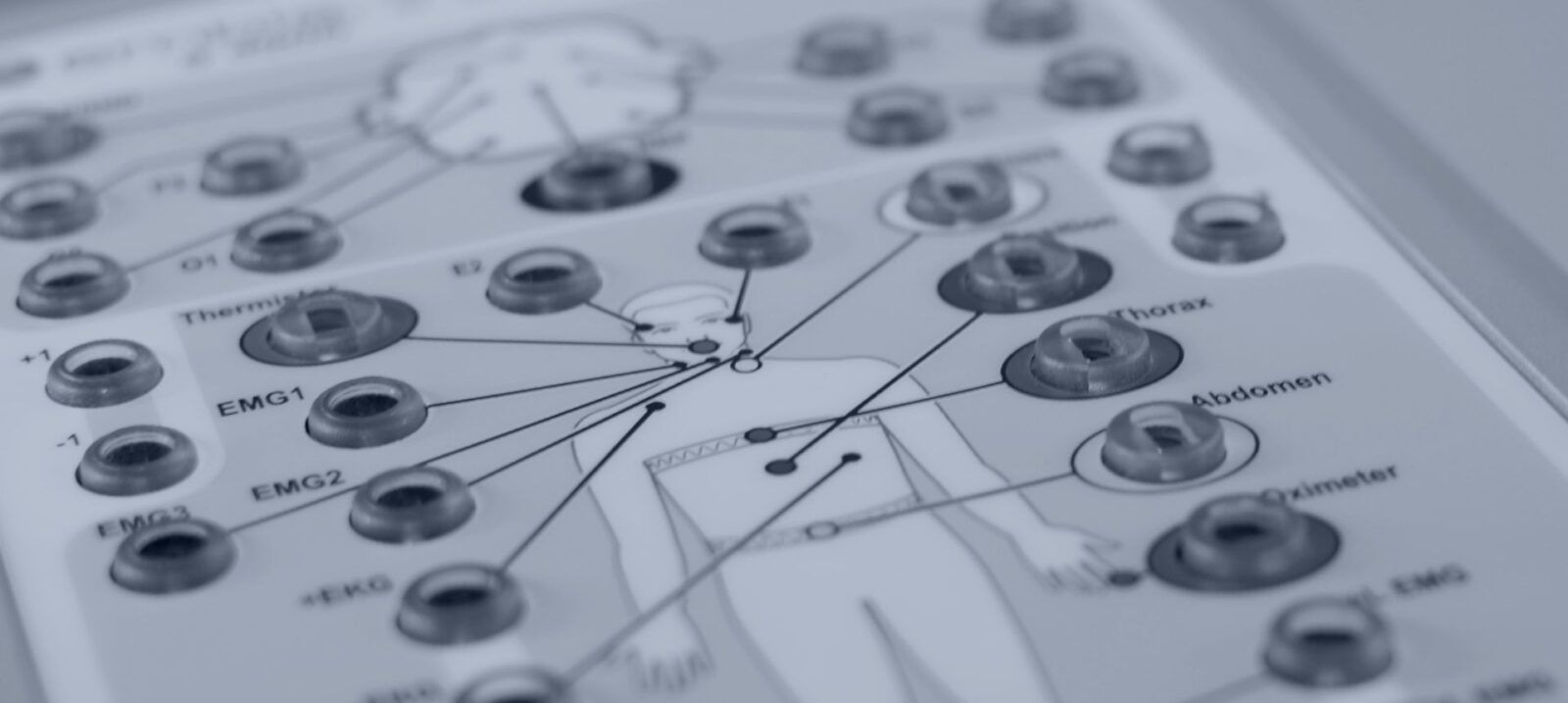

Clean Room Assembly - Consumables

Our two Class 7 clean rooms, validated to ISO 14644, providing GMP-compliant manufacturing spaces.

Cabling Assemblies & Wiring Harnesses

Everything from basic one wire cable assemblies through to complex custom build cable and wiring harnesses.

Project Engineering & Productionisation

Ensure your device is a commercial success with our expertise and experience in PFMEA and DFM, hot house planning and monitoring.

Medical Device Consultancy

Supporting your device through approvals, audits and legislations in order to get your life-enhancing products to those who need them.

Service & Repair

We offer a full service and returns facility for pro-active or reactive instances, including reporting for post market surveillance, and logistics organisation.

Changing the world isn't easy. Unless you're changing it with Cogent.

At Cogent Technology, we’re as invested in bringing your world-changing vision to life as you are.

We offer world-class facilities, cutting-edge technologies, and adhere to the highest quality standards (ISO13485, ISO14001, ISO9001 and FDA).

Our game-changing MaPs system enables us to proactively plan, monitor and progress your device build at all times, while audits can be undertaken in one room in one day.

Most of all, we’re constantly developing our team so that they not only have the skills and expertise, but also the genuine passion it takes to deliver a world-class service.

From concept to fulfilment - we're with you the whole way

The earlier Cogent engage on your New Product Introduction (NPI) journey, the more value we can add.

From an early stage DFMA review and the establishment of a robust supply chain we will support your project working alongside to validate your product readiness or series manufacture.

Once in production, working together, Cogent will underpin the smooth distribution of your product

and provide the service facilities to keep your device fleet working to specification.

Case Studies

Manufacturing 13,000 ventilators in 12 weeks? No problem. Building life-enhancing cancer diagnostics? Simple. Keeping clients for over 30 years? Easy. Read about some of our projects – and then find out what we can do for you.

Manufactured in the UK for clients around the world

There are so many advantages of manufacturing your device in the UK – and so many more when you manufacture them with Cogent Technology.

Here’s a taste of what we have to offer:

sq.ft. Facility

sq.ft. Manufacturing Area

sq.ft. Biological Room

sq.ft. Clean Rooms

Our market sectors

As a specialist CMO for life-enhancing devices, our clients range from blue chips to start-ups in the MedTech and GreenTech sectors, as well as pioneers in other key sectors.

Healthcare

One of the only UK CMOs with ISO 13485 and FDA approval, and boasting world-class facilities right here in the UK, Cogent Technology is the choice for healthcare companies seeking reliability, quality and expertise

GreenTech

The world is in more urgent need of sustainable technologies more than ever. At Cogent Technology, we are best placed to help innovative green tech companies get their product manufactured in a commercially successful way.

Key sectors

From telecoms and diagnostics to security and industrial, we have the experience, skills and regulatory expertise to manufacture life-enhancing products to world-class standards.

What our clients say

“We are very pleased with the quality and consistency of the finished product as produced by Cogent Technology. They demonstrate a consistently high level of skill, commitment and importantly flexibility in getting the product to our customer base. Furthermore, their design input has made a significant contribution to the overall product manufacturability and quality.”

“The innovation, collaboration and resolve you showed in taking up the gauntlet of the Ventilator Challenge has been inspirational. The design and engineering talent we have in this country is second to none… your achievements over such a short space of time are nonetheless remarkable, and justifiably a source of considerable pride for you and your company.

Once again, I would like to pass on the Government’s gratitude to you and your whole team.”

Contact Us

We look forward to working with you

Cogent Technology Ltd

Langer Road

Felixstowe

Suffolk, IP11 2BF

United Kingdom

+44 (0)1394 445566